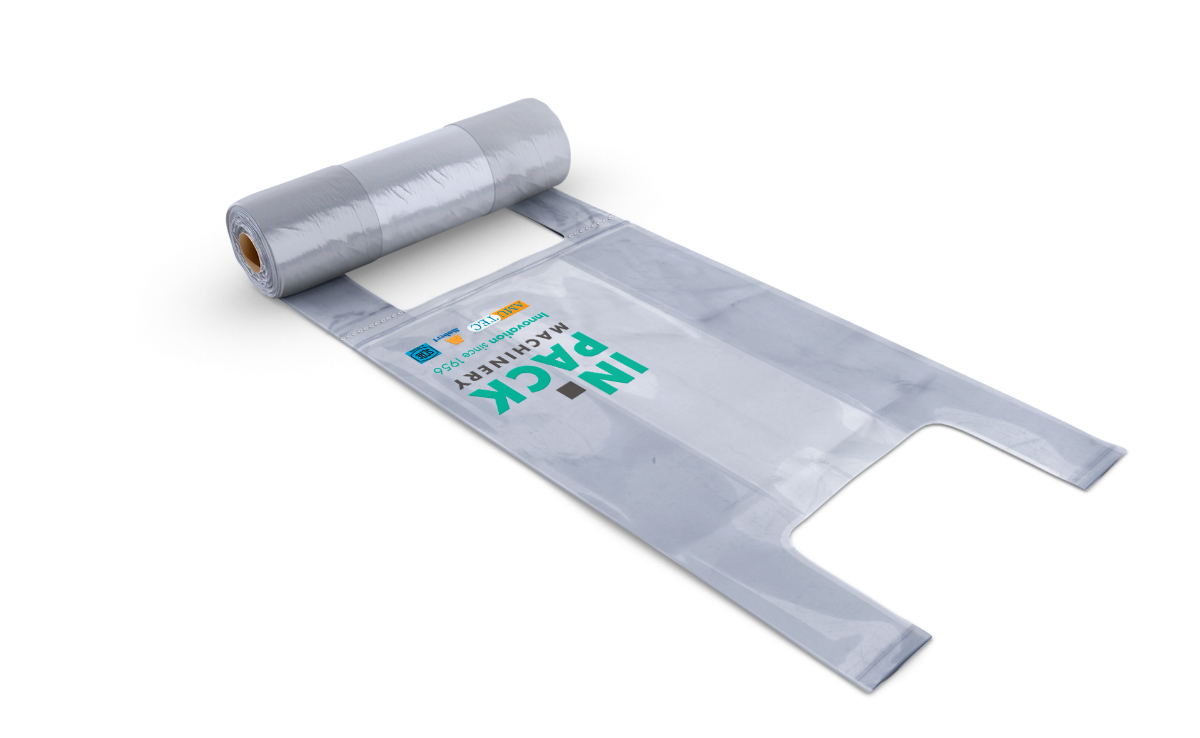

R2-C

Produce bag on roll with carton core

Version – AUT 2M

Line for the production of Open Mouth bags on up to 5 lanes (Roller 110/130); welding cutter device is adjustable in width. Automatic wrapping unit with 2 stations with expandable mandrels for continuous film wrapping with flying grip.

Version – SHP

Device for the production of Shopping bags on up to 4 lanes.

Version – ECO 2M

Line for the production of Open Mouth bags on up to 5 lanes (Roller 110) or up to 8 lanes (Roller 130). Adjustable width cutter device semi-automatic winding unit with two stations suitable for the formation of reels with a diameter of max. 200 mm.

| Technical Characteristics | Roller 110 E / 2M | Roller 130 E /2M |

|---|---|---|

| Min. bag width - Open-Mouth/Shopping bag | 100/220 mm | 100/220 mm |

| Maximum width | 230 mm | 300 mm |

| Min. bag length - Open-Mouth/Shopping bag | 250/800 mm | 250/800 mm |

| Max. bag length - Open-Mouth/Shopping bag | 1500/650 mm | 150/650 mm |

| Maximum roll diameter | 180 mm | 180 mm |

| Cardboard core internal diameter | 33 mm | 33 mm |

| Minimum film thickness (HPDE) | 0,010 mm | 0,010 mm |

| Maximum film thickness (LPDE) | 0,060 mm | 0,060 mm |

| Maximum mechanical speed | 250 cycles/min | 250 cycles/min |

| Maximum film speed | 150 mt/min | 150 mt/min |

| Total power consumption | 20 Kw | 22 Kw |

| Compressed air consumption | 800 lit/min | 800 lit/min |